Tipper Body Fabrication & Repair

Turnweld Engineering excels in tipper body fabrication and repair, delivering expert craftsmanship and tailored solutions for over 20 years. We cater to a wide range of industries, combining innovative approaches with unmatched quality to ensure vehicles operate at their best.

Tell Us About Your Project

Quality Fabrication Solutions

We are the Sunshine Coast's premier team for tipper body fabrication and repair. With an enduring presence spanning over 20 years, Turnweld Engineering has been diligently servicing Queensland, offering exceptional craftsmanship in the realm of metal and stainless steel works.

Specialising in custom solutions, our seasoned team efficiently caters to a range of industries, ranging from waste management to mining, through both in-house and mobile on-site services. Your vehicle, whether requiring meticulous maintenance or comprehensive body repairs, is in excellent hands. Contact us today to discover the undeniable quality of our tipper body services.

What We Do

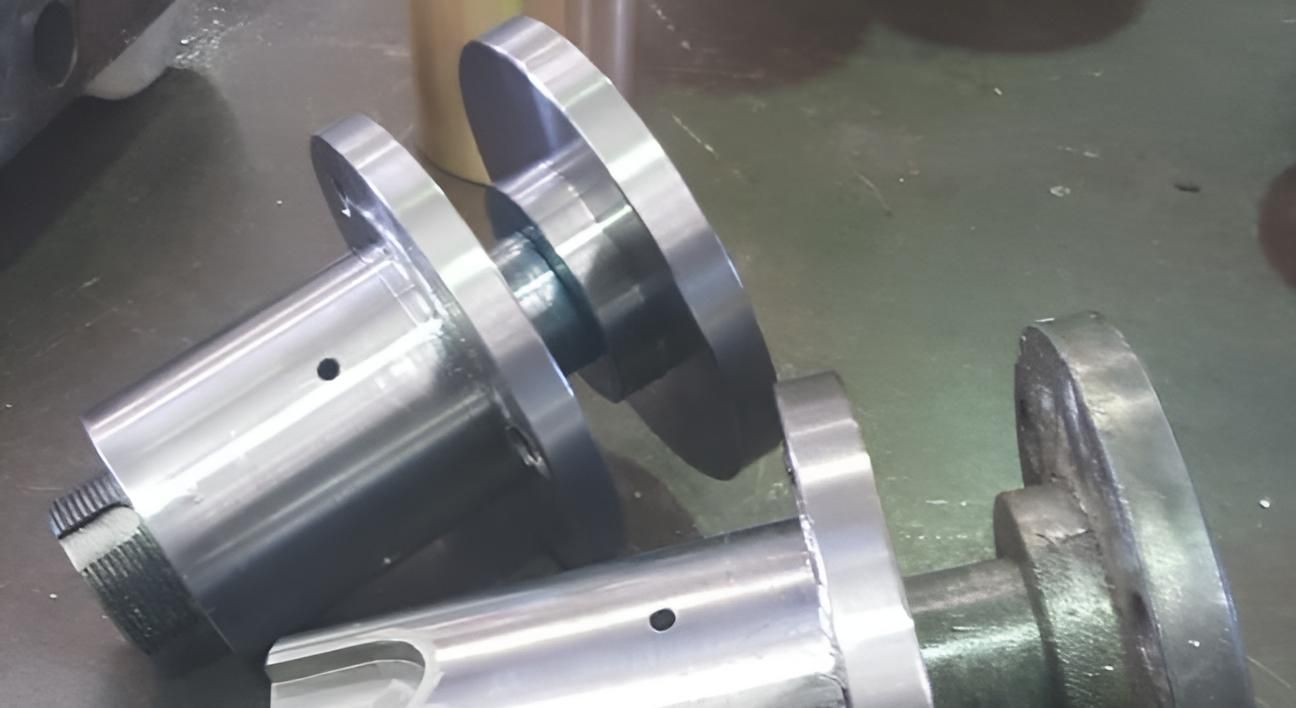

At Turnweld Engineering, we are artisans of metal, offering excellent service in the world of tipper body fabrication and repair. Our expertise lies in the meticulous crafting and repairing of tipper bodies for all models of utes, aligning with the highest standards of quality and precision. Utilising our resources and knowledge, each project is a testament to our understanding of a range of industry nuances. Our services offer innovation, proficiency, and unwavering commitment, ensuring that your vehicle operates at its pinnacle of performance and reliability.

Benefits

- Fits any type of single or dual cab ute

- Strong steel frame for either camper use or general-purpose tray use

- Designed in Australia, universal assembly for almost every length of ute and Van tray

Optional Extras

- Alloy trays, canopies, steel trays, and toolboxes

What Brands Do You Work With?

- Toyota, Ford, Mazda, and most ute types

Our Services

Turnweld Experience the pinnacle of convenience with our localised services on the Sunshine Coast. Our mobile equipment allows us to come to your job site or place of business to assess your truck and the fabrication and/or repair needs. Whether you're seeking minor modifications to your trucks or a large-scale project, our flexibility and expertise will save you both time and money.

Our refined approach minimises downtime, allowing for a seamless operational flow so you and your vehicles can get back to work as soon as possible. Embrace a service that comes to you, bolstering productivity and expediting project completion times with unparalleled professionalism and proficiency.

Our Workshop

Situated in the heart of Coolum on Queensland's vibrant Sunshine Coast, our workshop stands as a hub of innovation and excellence in tipper body fabrication and repair. Here, in an environment with state-of-the-art equipment and a team with unmatched workmanship, we bring your projects to life.

We work with a wide range of QLD businesses from an up-and-coming family business to a large-scale industrial company. Whether you're looking to repair parts of your fleet of trucks or utes or in need of bespoke fabrication for particular models, we're here to help. In our manufacturing workshop, convenience meets mastery, ensuring that each project meets our highest standards in customer service and steel manufacturing.

Our Team

Experience

When it comes to welding, craftmanship, aluminium, and steel fabrication, our team at Turnweld Engineering is the pinnacle of experience and dedication to delivering top-quality results in Australia. Our journey, rich with varied projects involving utes, vans, and commercial trailers, started in 1997 on the Sunshine Coast.

Specialising in a spectrum of services from tipper body fabrication to chassis design and tray modifications, our team seamlessly blends traditional techniques with innovative approaches. For a comprehensive quote or more info, please reach out to us and give us a call.

Quality

The certified craftsmen of the Turnweld Engineering team prioritise unparalleled quality and Australian industry standards. Our employees uphold a tradition of excellence with every project, whether it involves the precision of tipper body fabrication or the nuanced mechanics of ute and van body repair. They ensure that each task and every single product is unmatched in integrity. Quality isn't just a priority but a defining pillar of our business. We believe in working hard and getting the repairs done right first.

Frequently Asked Questions

Can Turnweld fabricate tipper bodies for both single and dual cab utes?

Yes, we can fabricate tipper bodies for both single‑cab and dual‑cab utes. Our steel-frame tipper bodies are designed in Australia and built to suit a wide range of ute lengths and cab configurations, ensuring that whether you have a standard single-cab or a dual-cab vehicle, our fabrication team can tailor the body accordingly.

What materials are used in tipper body fabrication?

Tipper body fabrication typically utilises strong structural steel frames, often with options for alloy trays, canopies, and toolboxes where needed—providing a durable base with lighter-weight elements for the top or side components. Our workshop can handle fabrication of steel, stainless steel, and aluminium, so the combination of materials is selected based on your needs, vehicle type, and use case.

Can you fabricate tipper bodies for all vehicle types?

Yes — we cater to a broad range of vehicle types. Whether you’re running a ute, van tray, or commercial vehicle that requires a tipper body, our experience across various fleets enables us to work with most models and configurations. That said, we continually assess the chassis, mounting points, and vehicle type beforehand to ensure the fabrication meets the required standards in fit, strength, and performance.

What is the turnaround time for a tipper body fabrication project?

Turnaround time can vary depending on the complexity of the design, vehicle type, materials selected, and current workshop load. Typically, for a standard ute requiring a steel-frame tipper body, you can expect a reasonably prompt schedule, given our efficient workflow and mobile/on-site services. We recommend contacting us early with your vehicle details so we can provide a tailored estimate.

What brands do you work with for tipper body fabrication?

We work with the most common vehicle brands used for ute and tray setups, including but not limited to Toyota, Ford, Mazda and other popular ute types—ensuring our tipper bodies are compatible and integrated adequately for those vehicles.